Modo

Turn a hardware idea into a buildable prototype

169 followers

Turn a hardware idea into a buildable prototype

169 followers

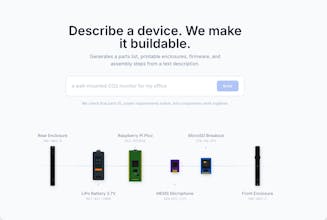

Modo turns a text description into a buildable hardware prototype with validated parts, printable enclosures, firmware scaffolding, and step-by-step assembly instructions.

Shimmer

@ethans100 This is brilliant Ethan, congrats on the launch. How far does it go component architecture and diagrams? Component suggestions?

Shimmer

@zolani_matebese It looks up the datasheet of each of the components and determines, based off the measurements, the appropriate CAD design to create. Then, it gives you the pricing for everything, including the CAD design.

The version 2 of this is to actually go through the checkout experience where it purchases all of the parts and sends the CAD for 3D printing for you.

@ethans100 Very cool project, congrats on the launch! Would like the abbility to stop it early though. Like when I can see that it's already diverge from my vison of the project to correct it.

Congrats on the launch — turning plain text into a fully buildable hardware prototype with real parts and enclosures is such a wild unlock for indie makers and hardware-curious software devs.

BlogBowl

Congrats on the launch! It's really impressive, I like the idea. I've experienced some bugs (wasn't able to write some followups, the Send button doesn't work), however I'm really impressed with how easy and straightforward the process was. Good luck!

Shimmer

@mrfullset appreciate it - not easy, even with LLMs to ensure all the parts fit, cad renders, etc.

Shimmer

@mrfullset Fixed it. The issue was when you're not logged in and in its anonymous build, you couldn't modify the chat, but now you can.

Constraining generation to real components + driving enclosure geometry off datasheet dimensions (vs “vibes”) is the right way to make AI hardware actually buildable 🔥 The scale pain is tolerance stacks + connector/thermal/EMI realities that aren’t in the BOM; best practice is parametric CAD (Replicad) with clearance rules, fast-fit test prints, and constraint checks (USB/headers/screw bosses) baked into the generator. How are you modeling tolerances/keepouts per part, and will you add an export to KiCad + a “vendor-available BOM” check (LCSC/DigiKey) next?

Cloudthread

Wow - super cool! Do you then link your users with relevant hardware builders/providers? Help on the supply chain side

Shimmer

@daniele_packard always open for support - this is a side project since for my main gig i needed to build a hardware project and i found myself doing all these steps manually.

Cloudthread

Cool - I'll try it out

Constraining generation to real components and datasheet-driven geometry is exactly the right move — that’s where most “AI hardware” demos fall apart.

Curious how you’re thinking about second-order constraints next: tolerances stacking up, connector clearance, thermal considerations, and EMI quirks that usually only show up after the first physical build.

If you can surface those risks early (even heuristically), this could become a serious bridge between software-minded builders and real-world hardware.

Congrats on the launch! Excited to see this product since many hardware founder friends always feel painful to find all parts to make their prototype. Wandering will you considering to connect with some 3d printing shop to allow more room for builders?